Carbon Electrode Paste Used for Metallurgical & Ferroalloy Industry

Rongxin Carbon Company has established for more than 25 years. Our factory is located in the middle area of China, Henan province. As the second largest factory of China, we dedicated to the research and development of carbon products such as electrode paste, Graphite Electrode and so on. The annual output is 200,000 ton for electrode paste. With the quality products, we have expanded our business to the whole world.

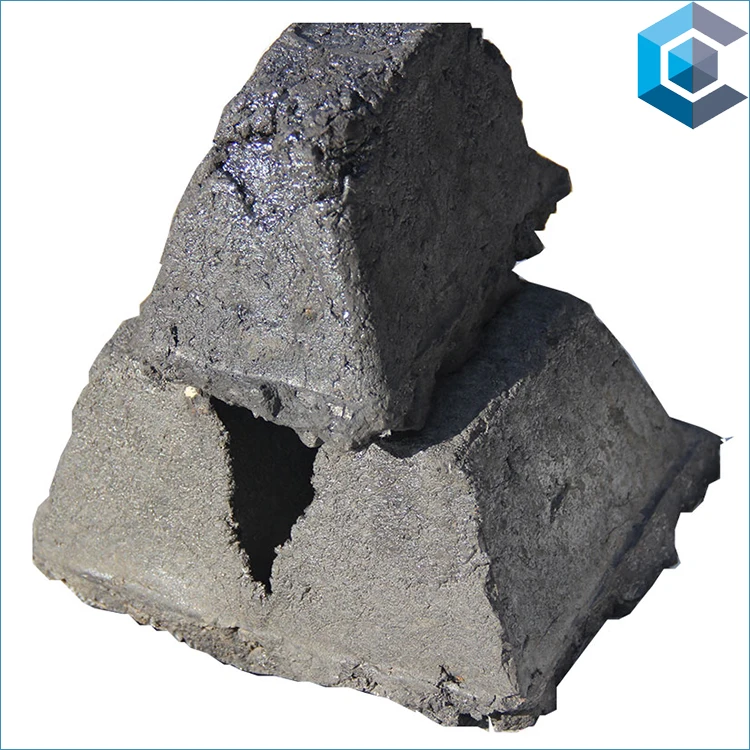

electrode paste is made by calcined anthracite, metallurgical coke, pet coke mixed with the bond agent pitch and coal tar. electrode paste is also called self-baking paste as it can be self baked by the heat in the submerged arc furnace. What's more, it is named soderberg paste abroad in Europe, Russia or in other areas.

electrode paste is high temperature resistance while the thermal expansion coefficient is very small. Thanks to the lower resistivity, it can reduce the loss of electric energy. With smaller porosity, electrode paste can low down the electrode oxidation in heating status. Carbon electrode paste play a significant role in the arc furnace, without it, the electric arc furnace can not work. Only the carbon materials can perfectly meet the demands that submerged arc furnace requested.

The key specifications for electrode paste are resistivity, ash content, volatile matter. Rongxin Carbon use premium raw materials to produce, the finished product will possess high standard specifications.

Regarding the shapes, we can supply trapezoid, oval and Cylinder electrode paste. The size can be regular ones and customized on your requests.

| Item | Parameter Value |

| Si | <0.28% |

| Fe | <0.25 |

| P | 0.00% |

| Ash content | 2-10% |

| Resistivity | 55-90μΩm |

| V.M. | 10.0-15.0 |

| Bulk Density | >1.46 g/cm3 |

| Compression Strength | >18Mpa |

| Apparent Density | >1.42 g/cm3 |

| Rupture Density | >4.0 |

| Real Density | >1.98 g/cm3 |

Our factory is located in Henan Province, the central area of China. The transportation is very convenient.

There are more than 50 workers in the plant and 20 staff in the foreign trade department.

1. Low ash content. After calcination in the furnace at a temperature above 1000℃, the dust in the raw materials is removed.

2. Advanced equipment. We introduce the automatic production system into our factory.

3. Vast inventory. With the output of 15,000 tons monthly, we can guarantee a timely and stable delivery for you.

4. Good reputation. So far, we have served more than 300 customers at home and abroad.

5. After-sales service. Most of companies in the market are not real manufacturers, they don't have the technicans. But we will provide a thoughtful after-service to our customers.

With honest heart, we win the world. The service of company can show its attitude to business and customers. We will request our customers to supply their specifications of their furnace, after studying on it, a most proper solutions will be given to our customers. More important, we will visit our customer regularly every year. Face to face, we can solve more problems that our customers have.

Package is very important. The bags we supplied are very wear-resisting during the shipping process.

Cooperated with famous and professional logistics agent, we can offer you various delivery ways.

1. Are you a trader of manufacturer here?

- We are a manufacturer for carbon products with more than 25 years experience.

2. Which countries have you sold your products to?

- We have sold our products to Italy, Iran, Malaysia, Indonesia, Pakistan and so on.

3. Will you provide samples?

- Yeah, the samples can be sent for lab testing.

4. What is your output for electrode paste and Graphite Electrode?

- The annual production capacity for electrode paste is 200,000 tons, and Graphite Electrode is 60,000 tons.

5. What's the applications for electrode paste?

- The electrode paste( soderberg paste) self-baking paste is used for ferroalloy, ferro silicon, silicon maganese, calcium carbide producing

.

- The second largest in the country

- Cumulative supply unit 330+

- Cost-effective than the peer 20%

- 48H rushed to the production site as soon as possible

UHP600X2400MM Graphite Electrode 200 tons in StockComing the end of this year, we have achieved a wonderful sale target even under corona impact. Right now we h.

The electrode paste is burned in a submerged electric furnace (sintered in an electrode barrel made of steel plate) and consumed, so it is also called a continu.

This week, 250 tons cylinder electrode paste 500x1000mm was finished and delivered to our Middle East customer. This customer is a high carbon ferrochrome prod.